产品简介

NABX全自动变压器频响法绕组变形测试仪(频响法)用于测试6kV及以上电压等级电力变压器及其它特殊用途的变压器,电力变压器在运行或者运输过程中不可避免地要遭受各种故障短路电流的冲击或者物理撞击,在短路电流产生的强大电动力作用下,变压器绕组可能失去稳定性,导致局部扭曲、鼓包或移位等永久变形现象,这样将严重影响变压器的安全运行。按国家电力行业标准DL/T911-2004采用频率响应分析法测量变压器的绕组变形,是通过检测变压器各个绕组的幅频响应特性,并对检测结果进行纵向或横向比较,根据幅频响应特性的变化程度,判断变压器绕组可能发生的变形情况。

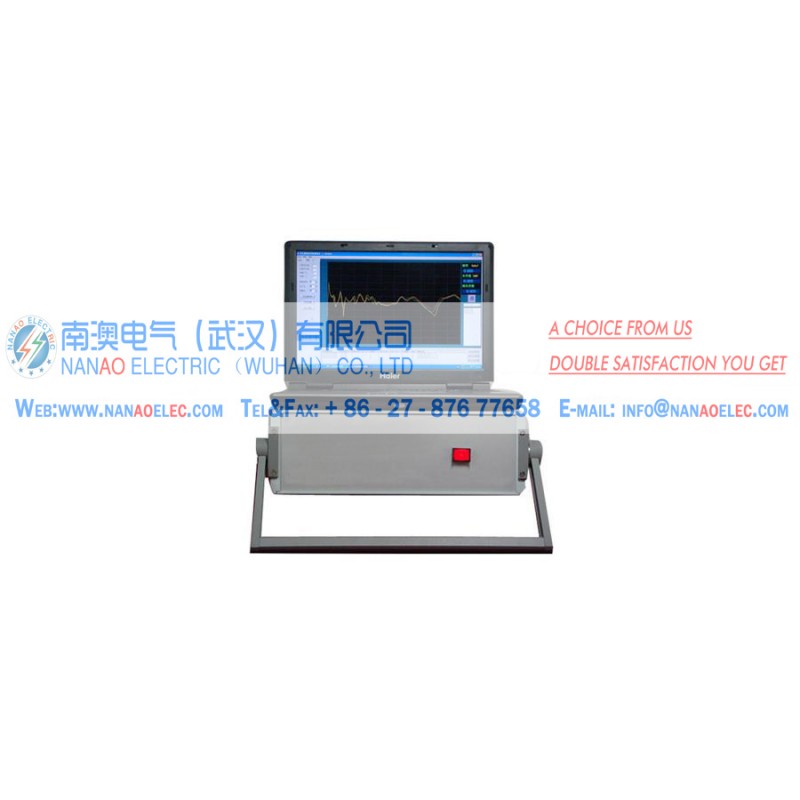

NABX变压器绕组变形测试仪(频响法)由测量部分及分析软件部分组成,测量部分是由信号生成及信号测量组成的黑匣子,分析部分由笔记本电脑完成,测量部分通过USB或网络与笔记本电脑连接。

产品别名

电力变压器绕组变形测试仪,变压器绕组变形检测仪,变压器绕组变形测量仪,变压器绕组变形分析仪

产品特性

1.不对变压器进行吊罩、拆装的情况下就可以进行测试。

2.使用目前最为流行的扫频法进行测量。

3.NABX变压器绕组变形测试仪可以对6kV以上的变压器进行测量。

4.采用分体式结构,测试主机与主控计算机之间采用USB或网络连接,即插即用。

5.现场接线简单、使用方便。

6.测量动态范围宽:-100dB~20dB。

7.分析软件功能强大,软件、硬件指标满足国标DL/T911-2004。

8.采用windows平台,兼容Window 2000/Window XP/Windows7。

9.采用数据库保存测试数据,对测试数据的管理简洁方便。

10.可以同时加载6条曲线,各条曲线相关参数自动计算,自动诊断绕组的变形情况,给出诊断的参考结论。

11.软件管理功能强大,充分考虑现场使用的需要,自动保存环境条件参数,以便作变压器绕组变形诊断时提供依据。测量数据自动存盘、具有彩色打印功能,方便用户出测试报告。

12.软件人性化特点明显,测量的各种条件多为选择项,不用在现场作很多的输入,使用人员更加的方便。

13.软件智能化程度高,在输入、输出信号连接好之后,只需要按一个键就可以完成所有的测量工作。

14.软件界面简洁直观。

产品参数

1.测试主机与PC接口:USB。

2.信号源:仪器自带一个通道信号输出作为扫频的激励信号;信号输出为标准正弦波,信号输出幅度可以软件调节,幅度可达Vpp10V,信号输出阻抗为50Ω。

3.两个采集通道,一个采集激励信号,一个采集响应信号,用于计算传递函数。

4.采集通道量化精度:12位。

5.采集通道静态误差可达:0.5%。

6.每通道存储容量可达:64K样点。

7.采集通道输入阻抗:1MΩ。

8.扫频测量范围:0.5kHz-2MHz。

9.扫描方式:采用线形分布或对数分布的扫频测量方式。

10.扫描频率精度:信号源输出正弦信号的频率精度不大于0.01%。

11.扫频测量频点:固定模式或用户自定义。

12.符合国家电力行业标准:DL/T911-2004。

Product introduction

NABX transformer winding deformation tester based on transformer internal winding characteristic parameters measurement, adopting the developed countries internal fault frequency response analysis (FRA) method, able to make accurate judgments on the transformer internal fault. once the transformer is manufactured, its coil and the internal structure is stabilized, therefore to a multi- winding transformer coil, if the voltage level is same, with the same windling method, around the system in the same way , the corresponding parameter of each coil (Ci, Li) should is determined. Thus each coil resulting frequency domain response is determined , which corresponds to the frequency spectrum between the three-phase coils having a comparable. Transformer turns occurs during the test , the interphase short circuit or a collision during transport , resulting in the relative displacement of the coil , and the short-circuit during operation and the fault condition causing the coil deformation due to the electromagnetic force , will make the distribution parameters of the transformer windings change. Thereby affecting and changing transformers original frequency domain characteristics, namely the frequency response and resonant amplitude variations occurring frequency offset and so on. And according to the response analysis method developed transformer winding frequency response tester, is such a novel transformer internal fault nondestructive testing equipment. It is suitable for 63kV ~ 500kV power transformer internal structure fault detection. Transformer winding deformation tester is inside the transformer winding parameters at different frequency domain response changes were quantified after treatment , according to the magnitude of the changes the size , frequency response magnitude of change , regional and response trends to determine internal transformer winding the degree of change , in turn, can according to the measurement results to determine whether the transformer has been seriously damaged , the need for a major overhaul .